Develop operational resilience with AIOps for manufacturing

Unify IT and OT seamlessly to reduce downtime, prevent plant disruptions, and protect OPEX costs.

Reduce downtime with visibility and analytics across corporate and plant operations

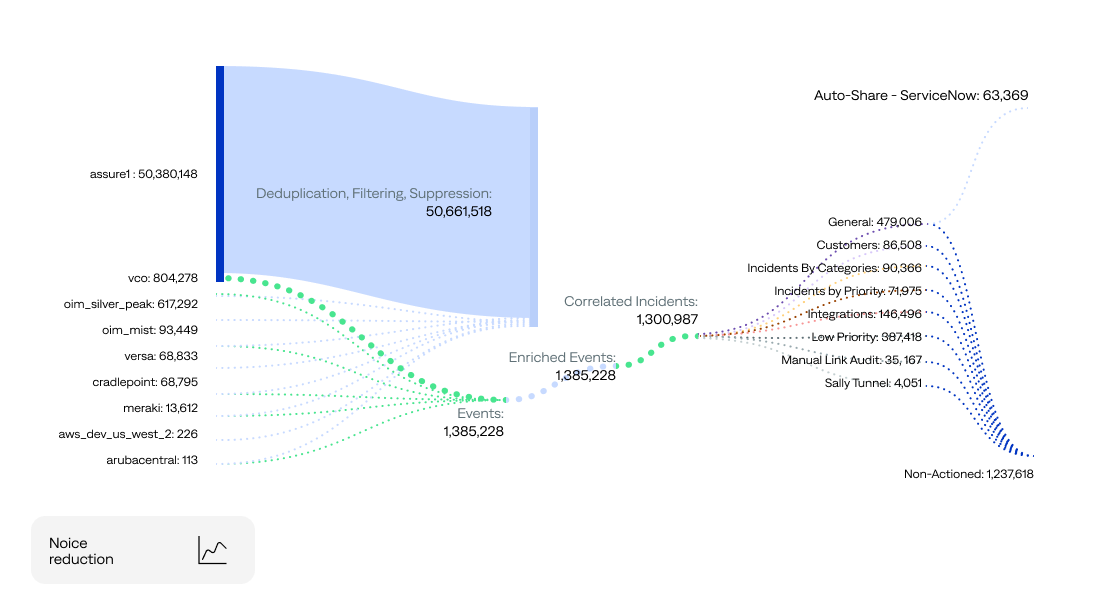

Bring together disjointed IT and OT teams and tools into a single platform so teams can quickly triage, detect, and investigate issues to reduce maintenance and outage time.

Reduce costs

With unified visibility and correlation across data sources, teams have the situational awareness needed to resolve issues faster and with fewer people, without impacting production lines.

Enable predictive maintenance

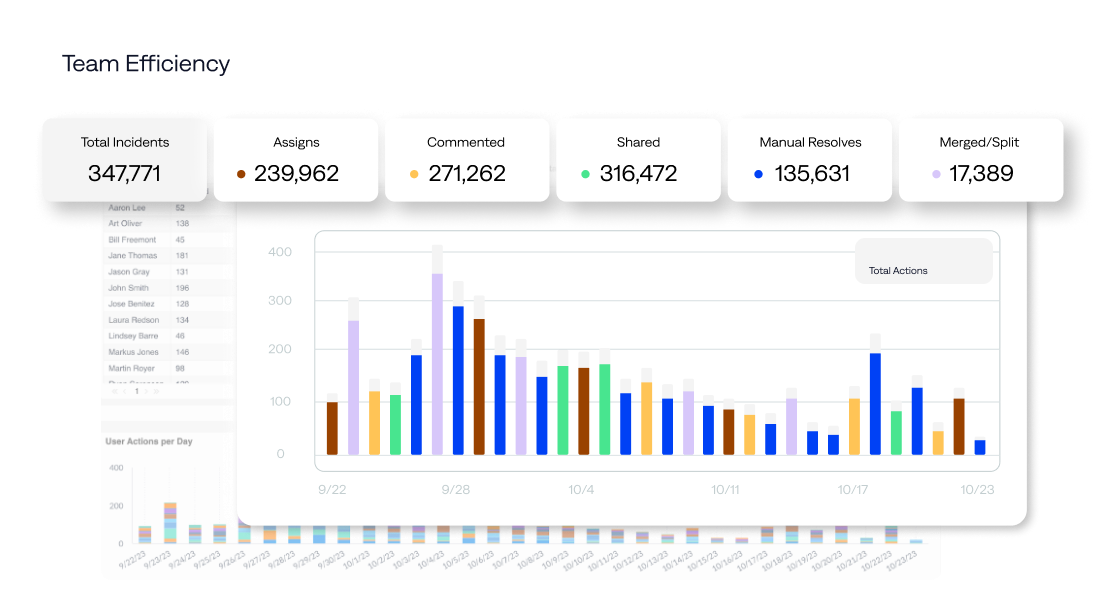

Unified Analytics allows your teams to proactively identify recurring issues, understand coverage gaps, and avoid equipment failures that result in maintenance-related downtime.

Prevent disruptions

Advanced Insight delivers AI-powered analysis based on change and historical data to identify repeat issues and recommend remediation steps, allowing operators to make fast, smart decisions that keep production lines running.

Reduce regulatory risks

Prevent quality issues and delays with operational and ITSM analytics that identify problems early and highlight opportunities for continuous improvement.

Agentic ITOps Platform

From firefighting to prevention: transform IT incident management with agentic IT operations

The power of AIOps on manufacturing

“With BigPanda, our IT noise is not only reduced, but we are able to identify root cause in real-time- who the responsible team is, who owns the service that’s alerting, etc. which is significantly reducing our MTTR.”

“As we scale and grow the business, it’s integral for us to bring in automation and integration with other tools and technologies. My recommendation is, don’t wait to start your AIOps journey once you are overwhelmed with alerts.”

FAQ

How does BigPanda support IT/OT convergence in manufacturing organizations?

Many large manufacturers have decentralized ITOps teams managing plant or warehouse systems and equipment and a centralized NOC for all core infrastructure. Connecting those two—called IT/OT convergence—is a complex process that has downstream impacts on team efficiency, downtime, and costs.

BigPanda integrates with legacy and modern infrastructure and applications. This allows manufacturers to integrate IT and OT systems seamlessly and gain visibility into dependencies between corporate and operational systems that will reduce downtime.

How does BigPanda use GenAI to help ITOps and Incident Management teams?

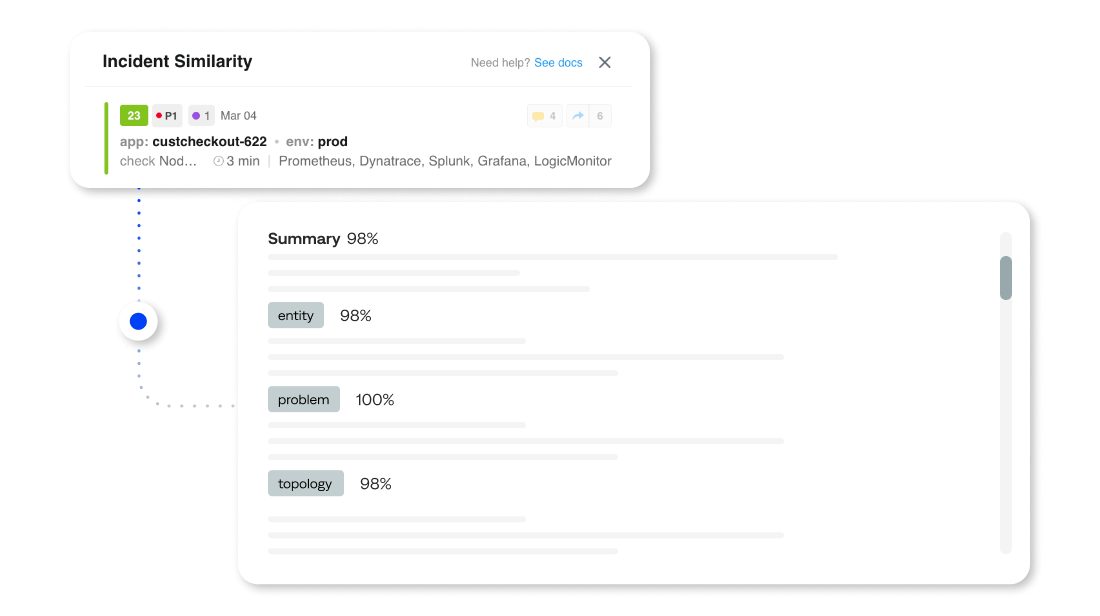

BigPanda Advanced Insight makes IT monitoring in manufacturing easier . Accelerating accurate assignments and reducing resolution times with GenAI-powered insights on change and historical incident data. This cuts critical minutes from the incident management lifecycle to lower MTTR and recover valuable FTE hours. Whether teams are working in BigPanda or their ITSM platform, they can access these insights.

For teams working incidents in Slack or Microsoft Teams, Biggy AI accelerates incident triage and investigation. Biggy AI combs through infrastructure data and knowledge to surface highly relevant insights that help NOC and Service Desk teams make smarter decisions, improve productivity, and scale incident management processes.

How can BigPanda prevent unplanned downtime related to maintenance?

Any downtime, whether planned or unscheduled, impacts output and revenue. Maintenance required to resolve or after an incident is costly, time-consuming, and inefficient. BigPanda Unified Analytics provides IT monitoring in manufacturing to analyze performance, identify repeat issues and coverage gaps so teams can resolve them before outages occur and additional maintenance is required.

Check out more related content

AN EVOLVED BIGPANDA

AI Detection and Response

The BigPanda platform you rely on is evolving. With powerful new capabilities for automated detection, triage, and response, BigPanda Core has evolved into BigPanda AI Detection and Response to help your enterprise take control of incidents before they escalate.